Korean Natural Farming (KNF) is a sustainable system developed by Master Han Kyu Cho of the Janong Natural Farming Institute in South Korea, based on generations of sustainable farming methods practiced in Japan, China, and Korea. KNF optimizes the production of plants or livestock through farming methods that maintain a balance in nutrient input and output, thus minimizing any detrimental effects on the environment. The balance is maintained by encouraging the growth of naturally occurring indigenous microorganisms (IMO), which in turn produce nutrients that are used in the production of crops and livestock. Virtually all of the inputs used in KNF, as compared to those used in conventional agricultural practices, are available locally at a fraction of the cost of imported feeds, composts, and fertilizers. Cultivation of IMO was covered in a previous publication (Park and DuPonte 2008). This bulletin covers the preparation of another KNF input, fermented plant juice (FPJ). What Is Fermented Plant Juice? FPJ is used in solutions for seed and soil treatments and plant nutrition. It consists of the young shoots of vigorously growing plants that are allowed to ferment for approximately 7 days with the aid of brown sugar. The brown sugar draws the juices out of the plant material via osmosis and also serves as a food source for the microbes carrying out the fermentation process. The weak alcohol produced during fermentation extracts chlorophyll (soluble in ethanol) and other plant components. It is non-toxic and edible.

What Affects the Quantity and Quality of FPJ? The most important requirement when selecting plants for making FPJ is to use the growing tips of plant species that are fast growers. Flowers, flower buds, and immature fruits can also be used. Hard or woody plant parts will yield little or no plant juice. The plants should be vigorously growing at the time of collection. Plant parts should be harvested while the plants are in respiration mode (before sunrise) and not in photosynthetic mode (during daylight), due to the effects these processes have on plant chemistry. Avoid collecting plant parts during or after rainfall (ideally, wait two sunny days after rain stops) and do not rinse collected plant parts, to conserve their surface microbial populations (lactic acid-producing bacteria and yeasts), which will carry out the fermentation process. Low levels of these microbes will result in improper fermentation and/or low yields of plant juice. What Kinds of Plants Can Be Used to Make FPJ? Plants should be vigorous, fast-growing, and healthy. In Korea, the most commonly used plants are mugwort (Artemisia vulgaris) and dropwort (Oenanthe javanica). Other ideal choices grown locally include, but are not limited to, purslane (Portulaca or pigweed), watercress, angelica (see Fig. 1), bamboo shoots, sweetpotato vines, beans, pumpkin, and seaweeds (Table 1). KNF practices emphasize using what is available. Do not use poisonous plants; if in doubt, have plants identified through your local extension service. When Is the Best Time to Make FPJ? FPJ can be made year-round in Hawai‘i. In temperate climates, FPJ is usually made during the warmer months when plant growth is vigorous and growing tips are abundant. Making Fermented Plant Juice (FPJ) Step 1. Collect plant material Before sunrise, collect the fast-growing tips (2–3 inches long) of plants; for plants with longer tendrils, such as sweetpotato, longer pieces can be collected. Avoid collecting during or after rainfall. Step 2. Cut and weigh the plant material Do not rinse collected plant parts, so as to conserve surface microorganisms. Record the weight of the

Table 1. Plants commonly used to make fermented plant juice (FPJ) Angelica Angelica sp. Shoot tips Bamboo Various genera Shoot tips Beans Various genera Shoot tips Dropwort Oenanthe javanica Shoot tips Mugwort Artemisia vulgaris Shoot tips Noni Morida citrifolia Immature fruit, Purslane Portulaca oleracea Shoot tips Seaweed Various genera Shoot tips Squash shoots Cucurbita spp. Shoot tips Sweetpotato shoots Ipomoea batatas Shoot tips Watercress Nasturtium officinale Shoot tips.

Cut the shoot tips into 2- to 3-inch pieces (Fig. 2). Weigh plant parts before or after cutting, whichever is easier. Step 3. Add brown sugar Weigh out an amount of brown sugar equal to the weight of the plant material, and toss together in a bowl or large pan. Coat as much of the surface area of the plant material with sugar as possible to expedite the osmotic process and draw out the plant juices (Fig. 3). Step 4. Pack the plant-material-and-brown-sugar mixture into a container Select a clear glass or food-grade polyethylene (PE) plastic container (no lid necessary). Do not use metal, which will react with the solution. Pack the container tightly with the plant-material-and-brownsugar mixture until full (Fig. 4). Cover the mouth of the container with a breathable material, such as muslin, heavy cheesecloth, or a towel, to allow air exchange. Secure the cover (with string, rubber bands, etc.) to keep pests and other contaminants out (Fig. 5). Paper towels can be used but should be replaced if they become wet or torn. Store the covered container in a well-ventilated area away from artificial or natural light and extreme heat or cold. Do not refrigerate. Step 5. Check the container after 24 hours and adjust the volume if necessary In order for the fermentation process to occur properly, the volume of the plant-material-and-brown-sugar mixture should settle to 2 /3 of the container after 24 hours. If the container is too full, the microbes will not have enough air to properly ferment. Remove some of the plant material until the container is no more than 2 /3 full. If the container is less than 2 /3 full, add more of the mixture to prevent mold growth. Not all plants will settle in the same way, so it is important to check and adjust the volume after the first 24 hours.

Step 6. Let the contents ferment undisturbed The fermentation process is dependent on ambient temperature. Hawai‘i’s warmer, humid weather speeds up fermentation (3 to 5 days), while cool or cold periods slow the process. You will know that fermentation is occurring when bubbles start to form, which normally occurs on the second day. Ideally, fermentation should take no longer than 7 days, as the quality of FPJ appears to diminish thereafter. Fermentation is complete when 1) the plant material floats and the liquid settles at the bottom (note: if too much brown sugar was used, this separation is not distinct); 2) there is a light alcohol smell due to breakdown of chlorophyll; and 3) the liquid tastes sweet, not bitter. Step 7. Separate the liquid from the solids After fermentation is complete (3 to 7 days), separate the plant material from the liquid using a colander or strainer. The spent plant material can be used as animal feed, or added to mixed compost (another input known as IMO#5). The liquid is Fermented Plant Juice (FPJ), which can be used immediately or stored in a loosely covered container. Step 8. Store the FPJ properly. Transfer the FPJ into a glass or food-grade polyethylene (PE) plastic container. The microorganisms in the solution are alive and continue to produce gases. The lid must be kept loose or the container can explode. As with all Korean Natural Farming inputs, each batch of KNF should be stored separately. They should be combined only when a solution is being mixed for immediate use. For long-term storage, add an equal amount of brown sugar by weight to FPJ to prevent it from souring.

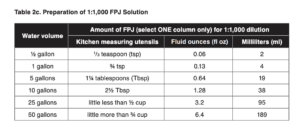

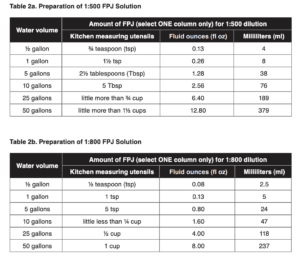

How Is FPJ Used on Plants? FPJ is diluted with water and applied as a soil drench or a foliar application directly onto plants. Traditionally, the plant material used in the fermentation process produces FPJ for specific phases of plant growth. Generally, use FPJ made from plant material at the same growth phase (vegetative or reproductive) as the plants that are to be treated. • FPJ made from dropwort, mugwort, or bamboo shoots is applied from germination until early stages of plant growth. • FPJ made from arrowroot or bamboo shoots is applied on vegetative growth (leafy) crops that need nitrogen (N). • FPJ made from green (unripe) fruit is applied to plants that are just beginning to develop flower shoots and need phosphorus (P). • Once plants reach the reproductive phase (flowering and fruiting), they require a lot of calcium (Ca). FPJ made from calcium-rich plants or FPJ that has been stored for over a year is applied at this stage. Preparing and Applying FPJ Dilute FPJ with water It is best to use a mixture of old and newly made FPJ in your solutions. FPJ is generally used at a concentration of 1 part per 500 parts water (1:500) (see Tables 2a–2c). A more dilute solution is necessary (1:800 to 1:1,000) to

avoid damaging plants (leaf burn) under the following circumstances: • more than three ingredients (a “cocktail” of different inputs applied at once) are being combined, or • it is applied during hot weather, or • FPJ that has been stored longer than a year and thus has become more concentrated is being used. Apply FPJ once per week in the late afternoon, ideally an hour before sunset The solution can be watered onto plants or into the soil, or it can be applied as a foliar spray. The nutrient solution is applied once per week and is adjusted as the plant passes through its life-cycle stages and vegetative and reproductive phases. Acknowledgements The authors would like to thank Dr. Russell Nagata, Ms. Ruth Niino-DuPonte, Mr. Andrew Kawabata, Dr. Erik Cleveland, and Ms. Sharon Motomura, who served on the peer review committee.